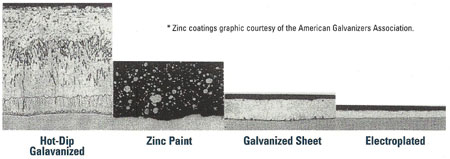

The hot- dip galvanizing process provides corrosion protection to mild steel components by coating and chemically bonding pure zinc to the steel substrate.

The process removes rust and scale by “pickling” in acid. The acid is washed away and dried prior to immersion in a bath of molten zinc.

We utilize any of the RAL colors as a standard selection. Our powder coating process offers a high quality durable finish. This painted finish can easily match any of your color needs.

Crittall products are powder coated and then painted in a wide range of available colors. Click the color chart to see all of the color options available. Please note, small orders may incur additional fees for custom colors.

In preparation for the polyester powder coating, the galvanized surface of the windows and doors is chemically cleaned and chromated. The prepared surface will now accept an electrostatically sprayed epoxy-free polyester powder coating AAMA 603 605. A minimum coating of 60 microns (0.002 inch) is applied to ensure excellent exterior durability and color retention.

Polyester powder coating is one of the most durable protective coatings for hot-dip galvanized steel; although it is not necessary to protection against corrosion, the duplex system is especially long lasting. With proper maintenance, and taking into account environmental and climate conditions, life expectancy of the polyester powder coating can be as long as 75 years (American Galvanizers Association “Duplex Systems: Painting over Hot-Dip Galvanized Steel”).

To learn more about Steel Windows & Doors

To learn more about Steel Windows & Doors

and our entire product line, please contact us directly.